|

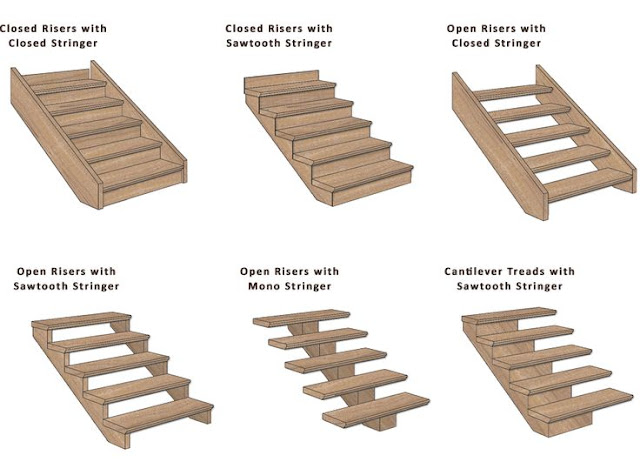

| credits to BuildingHow.com |

From the plans, we can count the number of rebars used (D12mm). For isolated footing, bars are usually placed both ways, hence, the number of bars laid horizontally is the same number laid vertically. For the length of the bars, specification already shows the clear length and hooks' length.

Commercial lengths can be exactly divided by 1.50, so it's the estimator's discretion on which commercial length the rebars be converted.

#16 GI Tie Wire:

D12mm rebars can be tied using 25cm wire.

Back to 7.0. Estimating Concrete Reinforcement